There is an urgent need to adopt integrated innovative product development strategies to meet the ever-changing customer expectations. This course, through theory and practical classes, aims to look at these issues and create an awareness of innovative product development process and various design methods to achieve success.

Product Design & Development is best learned by applying structured methods to ongoing project work in either industrial or academic settings. Therefore, we intend this course to be used as a guide to completing development tasks either in the context of a course project or in industrial practice.

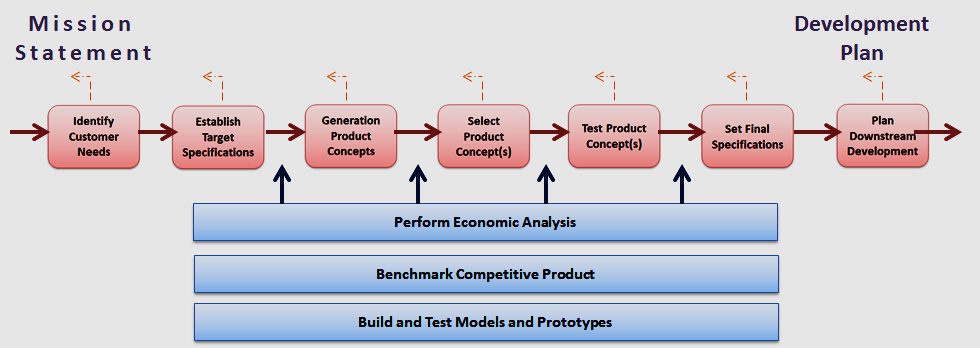

The process of identifying customer needs is an integral part of the larger product development process and is most closely related to concept generation, concept selection, competitive benchmarking, and the establishment of product specifications.

A Product Design Specification (PDS) is a statement of how a design is made, what it is intended to do, and how far it complies with the requirements Product Design Specification is one of the elements of Product Lifecycle Management.

Idea generation refers to the systematic search for new-product ideas. Typically, a company generates hundreds of ideas, maybe even thousands, to find a handful of good ones in the end.

Concept selection is the process of evaluating concepts with respect to customer needs and other criteria, comparing the relative strengths and weaknesses of the concepts, and selecting one or more concepts for further investigation, testing, or development.enchmarking, and the establishment of product specifications.

The Industrial Designers Society of America (IDSA) defines industrial design as “the professional service of creating and developing concepts and specifications that optimize the function, value, and appearance of products and systems for the mutual benefit of both user and manufacturer.

Ergonomics (or human factors) is the scientific discipline concerned with the understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles, data and methods to design to optimize human well-being and overall system performance.

Design for Manufacturing and Assembly (DFX) is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing and refining the product design.

Prototypes can be usefully classified along two dimensions. The first dimension is the degree to which a prototype is physical as opposed to analytical. Physical prototypes are tangible artifacts created to approximate the product. Aspects of the product of interest to the development team are actually built into an artifact for testing and experimentation. Analytical prototypes include computer simulations, systems of equations encoded within a spreadsheet, and computer models of three-dimensional geometry.

In engineering, a mechanism is a device that transforms input forces and movement into a desired set of output forces and movement. Mechanisms generally consist of moving components that can include: Gears and gear trains.

Finite Element Analysis (FEA) is a computerized simulation for predicting how a product reacts to real-world forces, vibration, heat, fluid flow and other physical effects. Finite element analysis shows whether a product will break, wear out or work the way it was designed.

IP RATINGS FOR ENCLOSURE DESIGN: The IP (or “Ingress Protection”) is a rating international standard, EN 60529 (British BS EN 60529:1992, European IEC 60509:1989) are used to define levels of sealing effectiveness of enclosures against intrusion from foreign bodies (Solids, Dust, Dirt etc.) and moisture.

Good metal casting design means creating the simplest mold that will produce a desired shape. This process requires expert knowledge of metals and casting methods to find the best value in a quality casting.

Injection molding has been one of the most popular ways for fabricating plastic parts for a very long time. They are used in automotive interior parts, electronic housings, housewares, medical equipment.

The process of duplicating an existing component, subassembly, or product, without the aid of drawings, documentation, or computer model is known as reverse engineering.

Manufacturing drawings show numerous features of a part that a 3D model doesn’t. For instance, drawings show the material type, the finish, dimensions, hardware, company information, and other specific requirements. The sole purpose of a drawing is to show all the details of a part.

Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describe nominal geometry and its allowable variation. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each controlled feature of the part.

At CADD Mentors – School of Design, our training approach is 100% practical oriented, So you’ll be Learning and gauges by the quality of the work & would understand what actually Design is? However, there are project-based exams for final assessment.

CADD Mentor’s Best industry-experienced Trainers are the subject matter specialist in their respective domains with excellent teaching skills. We Maintain a team of subject guru, So you would love to learn from them. Our trainers will help you to up skills your knowledge and potential, and make sure you achieve your desired goal in the industry.

Our Courses are designed as per industry needs with our extensive research. We make sure that you are learning the subject and upgrading yourself at par with the industry standards. All of our courses are updated regularly with the latest update releases and technology trends followed by industry.

CADD Mentor’s Best industry-experienced Trainers are the subject matter specialist in their respective domains with excellent teaching skills. We Maintain a team of subject guru, So you would love to learn from them. Our trainers will help you to up skills your knowledge and potential, and make sure you achieve your desired goal in the industry.

All of our programs are designed basis for extensive research done on industry standards. We do the regular check and keep our content updated by subject matter experts.

We are technology driven company, we believe in training our students in the latest version of the software, So that once they are going out for job, they should be up as per market standards.

What's Included

Request a call back

Student's Reviews

Join Our Most Popular and highly rated Course. Contact our course Advisor Now.

Have a Question?

FAQs

We are here to help you 7 days a week and response within 24 hours. Also, you can find most answers to your questions right on this page.

Any Mechanical Engineer with the zeal to learn and grow in the field of Product Design and Development should join this Course. Our Master Diploma in Product Design and Development are Designed for both who are new to the industry & wants to get into the Product Design and Development to add more experience.

Eligibility for admission to Master Diploma in Product Design and Development is Mechanical Engineering.

We have designed six months course to acquire skills and to meet the industry standards.

Along with the good quality training and also, we provide 100% placements assistance.

We train students such a way that they will be paid best in the industry.

Our training methodology is completely designed in such a way that students would be involved more on practical aspects, so that we can make them industry ready from the day one, this pattern of training clarifies all their doubts and indirectly prepares them to face any kind of interview. We will assist student with resume preparation and to face fearless interview.

Recommendation

Discover CATIA’s sketching, part modeling, assembly, sheet metal, surfacing, and drafting workbenches.

NX CAD is a 3D modeling software for realistic concepts Design and modeling. It is integrated and advanced CAD, CAE, and CAM solutions.

3D CAD system that combines ease-of-use with powerful modeling capabilities that can handle your most complex design projects.

Do you want to learn CAD Designing ? You can contact us below to get in touch with us and start your learning journey. We will contact you as soon as possible .

“Digital design is like painting, except the paint never dries.” -Neville Brody

Imagin | Design | Develop

CADD Mentors © All rights reserved

we are Here

To Assist You

Something isn’t Clear?

Feel free to contact us, and we will be more than happy to answer all of your questions.

Join us for the

Unlock your potential with expert-led courses at CADD Mentors.

Request for a free Demo !